News Center

Properties:

High Strength:

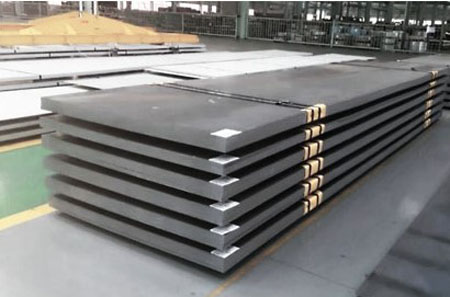

AH36 steel offers high tensile strength, typically in the range of 490-620 MPa, providing structural integrity and load-bearing capacity for marine applications.

Good Weldability:

Exhibits good weldability characteristics, allowing for ease of joining through various welding methods while maintaining mechanical properties in the welded area.

Corrosion Resistance:

Shows decent corrosion resistance, crucial for prolonged exposure to marine environments where rust and corrosion can compromise structural integrity.

Impact Resistance:

Provides good impact resistance, essential for ship structures subjected to dynamic loading conditions from waves and harsh marine environments.

Formability:

Offers good formability, enabling shaping processes like bending, forming, and cold drawing without sacrificing its strength and integrity.

Low Temperature Toughness:

Maintains good toughness at low temperatures, important for operations in colder climates or Arctic regions.

Applications:

Shipbuilding:

Widely used in the shipbuilding industry for constructing hulls, decks, superstructures, and other critical components of ships and offshore structures.

Offshore Structures:

Employed in the construction of offshore platforms, oil rigs, and marine infrastructure requiring high-strength materials with excellent weldability and corrosion resistance.

Marine Equipment:

Utilized in marine equipment such as navigational systems, propeller shafts, and marine cranes due to its high strength and durability in marine environments.

Naval Vessels:

Found in the construction of naval vessels, submarines, and warships where superior strength, impact resistance, and corrosion protection are essential.

LNG Carriers:

Used in the fabrication of LNG (liquefied natural gas) carriers for transporting gas across oceans, requiring materials with high strength and low-temperature toughness.

Offshore Support Vessels:

Commonly employed in the manufacture of offshore support vessels like supply ships, crew boats, and anchor handlers due to its reliability in demanding marine conditions.

Considerations:

Quality Control: Adherence to stringent quality control measures is crucial to ensure compliance with industry standards for shipbuilding materials.

Surface Treatment: Implementation of proper surface treatments and coatings to enhance corrosion resistance and longevity in marine environments.

Certification: Certification by classification societies such as ABS, DNV GL, or Lloyds Register is often required to verify material quality and suitability for marine applications.

AH36 grade shipbuilding steel is a vital material in the marine industry known for its high strength, weldability, corrosion resistance, and impact toughness. Its application in shipbuilding, offshore structures, marine equipment, and naval vessels underscores its significance in ensuring the safety, durability, and performance of maritime assets operating in challenging marine environments.

GB T 5312 Carbon and carbon-manganese steel seamless steel tubes and pipes are mainly for ship use, also known as shipbuilding steel pipes. Under GB T 5312, there are mainly 5 steel grades: grade 320, 360, 410, 460 and 490. Each grade covers three levels: I, II, III.

Angle steel, commonly known as angle iron, is a long strip of steel whose sides are perpendicular to each other. There are equal angle steels and unequal angle steels. The two sides of equal angle steel are equal in width. The unequal angle steel is also known as L shape profile steel.

Flat bar steel can be produced according to the user's needs, with fixed thickness, width and length. It can reduce the cutting process for users, reduce the consumption of labor and materials, and also reduce the processing loss of raw materials.

Bulb flat steel for shipbuilding

The bulb flat steel is a kind of medium section material which is mainly used in the field of shipbuilding and bridge building, and the shipbuilding bulb flat steel is an auxiliary medium section material for shipbuilding.

The steel for shipbuilding and oil platform---FH40, is the high tensile strength steel.The shipbuilding steel FH40 is the Hull structural steel.We can provide FH40 shipbuilding steel plate price.

The steel for shipbuilding and oil platform---EH40, is the high tensile strength steel.The shipbuilding steel EH40 is the Hull structural steel.We can provide EH40 shipbuilding steel plate price.

If you are interested in our company or products, welcome to visit our company or local offices; you can also get contact with us through online consulting, demand table submission, e-mails and telephones. Our staff shall wholeheartedly provide product information, application knowledge and good service for you.

BBN SHIP STEEL FACTORY

BBN SHIP STEEL FACTORY